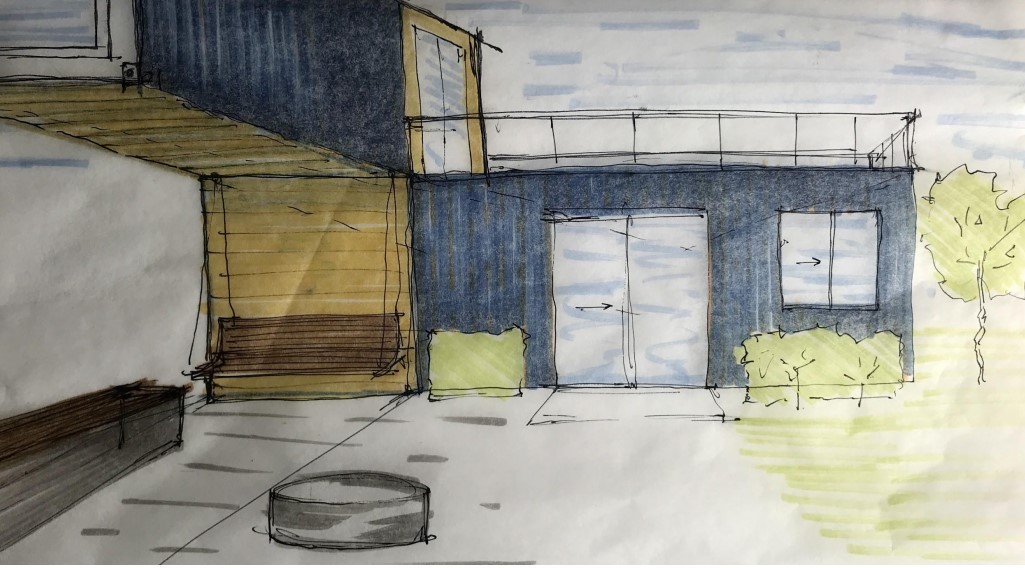

1.) Waterproofing

Unlike traditional construction which relies on many layers to create a watertight building, the structure and siding of a container are one and the same. Without siding, building wrap, or traditional flashing often the only thing keeping water between the inside of the building and the outside is caulk.

Containers are made of metal. Metal expands and contracts a lot, often resulting in caulk failing. We recommend detailing openings for doors and windows to allow welded drip edges above, highly flexible caulk, and self adhesive flashing covered with trim.

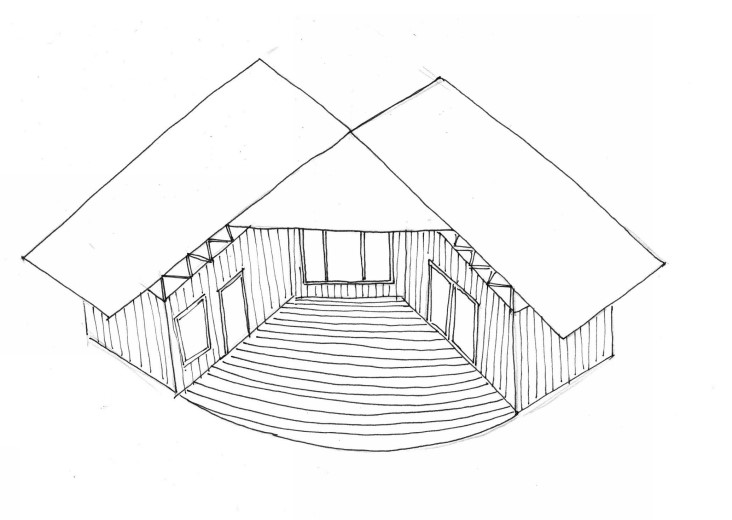

2.) Flat Roof

The top of a shipping container is flat and does not easily shed water or snow. Consider adding a roof with eaves over the top of the structure to further reduce the chances of leaking.

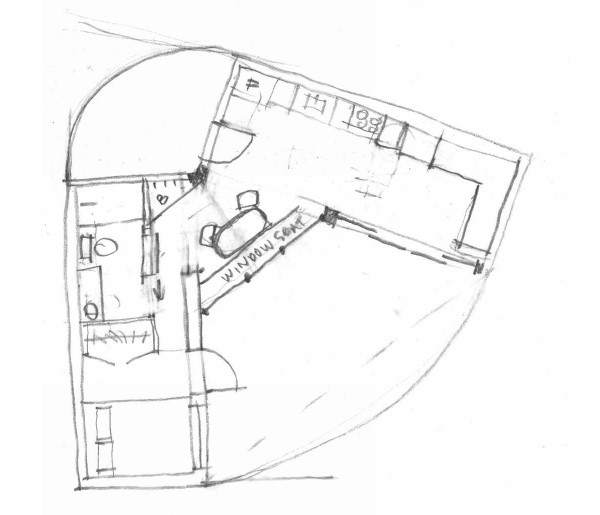

03.) Space

To fit on railcars, shipping containers are 8 feet wide. By the time you add insulation and drywall on the inside, they are often just over 7 feet wide on the interior. This is comparable in size to a boat or RV. Like boats or RVS, container buildings should include built-in elements that maximize space. Also, consider combining multiple containers or adding traditional construction to your containers to maximize space. Also, consider spacious decks that expand living outdoors.

4.) Structural Fun

Because containers are designed to fit on rail cars and to be stacked many high, they are extremely structurally sound. They can withstand a heavy snow load or be cantilevered or designed to span like a bridge in a way that would be challenging with traditional building techniques.

5.) Thermal Bridging

Just like a glass filled with ice water on a hot day, the metal structure of a container can result in a fair amount of condensation on the interior walls. Careful detailing and ventilation should be incorporated to minimize thermal bridging. We might even recommend adding a layer of rigid insulation on the exterior and adding metal siding that mimics the container ribs. This will both reduce thermal bridging and help with waterproofing.

6.) Fireproof

As fires in the northwest become more and more of an issue, containers can provide a fairly simple way to create a fireproof building. The doors can cover windows and protect them from burning. Adding metal skirting will protect the wood floor structure. Non-combustible/spark proof vents should be utilized to prevent sparks from entering into the structure.